Pure metal powders and alloy powders are the two most crucial metal powders. Alloy powders are generally thought to be better than pure metal powders. Is that correct, though? What are their respective advantages and disadvantages? This article begins with these questions.

To comprehensively understand whether alloy powders are superior to pure metal powders, it is first necessary to clarify their definitions and differences.

Pure metal powders refer to powders composed of one metal element. The powders are comprised of only the desired metal throughout the manufacturing process, apart from alloying elements, e.g., titanium powders (Grade 1-4). Due to their single-element composition, pure metal powders are more consistent in material properties.

Alloy powders are powders that are made by physical or chemical mixing of two or more metal components. Alloy powders result in complementary and enhanced performance of the metals. Ti-6Al-4V powder, niobium C-103 powder, Ta2.5W powder. High-entropy alloy powders are also a prevalent type of alloy powder.

Different elemental compositions naturally lead to significant performance differences between the two.

Alloy powders are typically of higher hardness and strength. It's because the solid solution strengthening, precipitation strengthening[1], and phase transformation strengthening[2] mechanisms are provided by the alloying elements. In contrast, the constitution of a single metal element is quite simple, and its mechanical properties are limited by the inherent nature of the metal itself. Pure aluminum powder, for example, possesses satisfactory ductility and electrical conductivity but low strength. By incorporating alloying elements, its mechanical properties can be significantly enhanced. For instance, by incorporating aluminum and vanadium elements in Ti-6Al-4V powder, titanium not only gets hardened and strengthened but also gets enhanced in ductility. High-entropy alloy powders are also a typical example of performance enhancement after alloying.

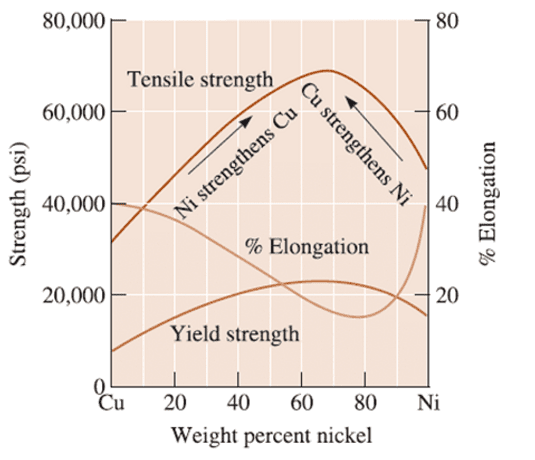

Figure 1. Effect of alloying Nickel with Copper

Figure 1 shows how the yield and tensile strength change with increasing amounts of Nickel added to copper.[3]

But this does not mean that all alloy powders have improved mechanical properties compared to pure metal powders. When the addition is of soft elements such as magnesium or tin, the metal can actually become softer. It is also important to mention that when one says alloy powders have improved mechanical properties, it is a comparison with the same element. For example, the aluminum alloy powder's hardness is not comparable to pure tungsten.

Alloy powders tend to exhibit higher corrosion resistance compared to pure metal powders. The alloying elements can create more stable and compact surface oxide layers during the addition.

Pure iron powder, for example, will rust under oxidizing conditions, decreasing the corrosion resistance. However, with additives such as elements of chromium, nickel, or molybdenum, corrosion resistance is greatly enhanced. At a reasonable proportion of composition, stainless steel powder can even be formed.

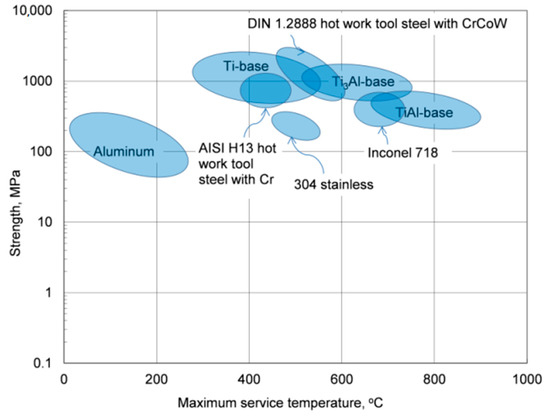

Alloy powders generally have better thermal stability with superior mechanical properties and structural stability at high temperatures. Pure metal powders may experience grain growth and loss of mechanical properties at high temperatures. Upon addition of alloying elements, melting point and creep resistance may be improved. Titanium alloys with molybdenum and tungsten, for example, lose very little mechanical property even at high temperatures.

Figure 2. Strength versus maximum service temperature for aluminum and alloy materials[4]

Although some alloy powders possess adequate mechanical and corrosion properties, their electrical and thermal conductivity is generally inferior to that of the corresponding pure metals. The electronic structure of the material is altered by alloying components, creating new energy levels or altering the effective electron mass. This, in turn, can affect the material's ability to conduct electricity and heat.

Summary:

|

Performance |

Pure Metal Powders |

Alloy Powders |

Exceptions |

|

Hardness |

Lower |

Generally higher |

Alloys containing soft elements may be softer than pure metals |

|

Strength |

Lower |

Significantly enhanced |

Certain brittle alloys may have lower strength than pure copper |

|

Corrosion Resistance |

Generally poor |

Usually better |

Pure precious metals have extremely high corrosion resistance, most alloys cannot surpass them |

|

Wear Resistance |

Lower |

Greatly improved |

Pure molybdenum/tungsten have better wear resistance than some light alloys |

|

Thermal Stability |

Fixed melting point, softens easily at high temperatures |

Excellent high-temperature resistance |

Pure refractory metals like tungsten have far superior thermal stability compared to most alloys |

|

Electrical Conductivity |

Excellent |

Generally reduced |

Minor alloying has minimal impact on electrical conductivity |

|

Thermal Conductivity |

Higher |

Generally decreased |

High-purity alloys have thermal conductivity close to pure metals |

|

Biocompatibility |

Usually better |

May be limited |

Specific alloys can combine biocompatibility and strength, such as Pt-Ir |

The answer is obviously NO.

Alloy powders are not necessarily stronger than pure metal powders; it simply depends on composition and application. For example, pure copper powder has much greater electrical conductivity than bronze powder (Cu-Sn) because the addition of tin reduces the electrical conductivity. Similarly, pure aluminum powder is softer and has greater ductility than some aluminum-silicon alloys (Al-Si) and is therefore best suited for use in applications involving bending and shaping. In short, alloying will be capable of enhancing hardness or corrosion resistance, but can also lose other characteristics.

In medical science, pure titanium powder (Grade 2) is more biocompatible than titanium alloys (such as Ti-6Al-4V), which are stronger. Pure titanium can thus be used for heart stents, while titanium alloys must be used for artificial joints. So there is no absolutely better material, but materials better suited to some purposes.

Stanford Advanced Materials (SAM) specializes in providing high-purity metal powders and alloy powder products. For detailed technical specifications or customized services, please contact our technical team. Get A Quote

[1] Precipitation Strengthening, https://www.imetllc.com/precipitation-strengthening/

[2] Chen, Jinmei & Jiang, Xiaosong & Sun, Hongliang & Shao, Zhenyi & Fang, Yongjian & Shu, Rui. (2021). Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys. Nanotechnology Reviews. 10. 1116-1139. 10.1515/ntrev-2021-0071.

[3] Solid Solution Strengthening, https://www.ilearnengineering.com/manufacturing-industrial/solid-solution-strengthening

[4] Czerwinski, F. Thermal Stability of Aluminum Alloys. Materials 2020, 13, 3441. https://doi.org/10.3390/ma13153441

United States

.png)