Defense contracts require materials that are proven to be good in terms of quality and reliability. The list hereunder comprises those that meet rigorous requirements. Each item has documented use and reliable sources. It is not exhaustive, but it gives you a good idea.

They are firstly very common, certified aluminum alloys. They are 7075-T6 and 6061-T6 alloys. They get into aircraft components and vehicle parts. They are light in weight but strong and suitable for military applications. Defense contractors have switched to these alloys for most critical parts due to tests having proven long-term performance. Test cases show that aluminum alloys offer durability and corrosion resistance. They pass tough quality tests.

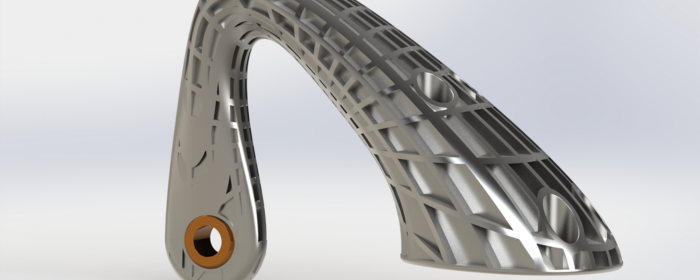

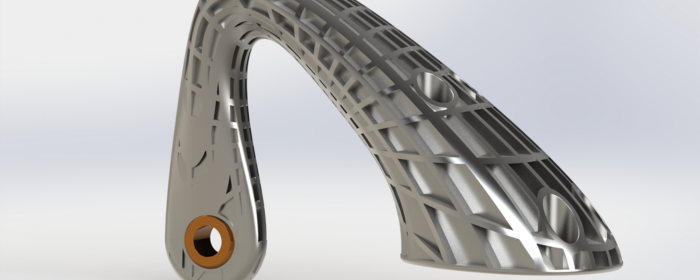

Then come titanium alloys. Titanium is strong but light. It is suitable for high-stress use. Jet engine and missile parts use titanium parts. They withstand heat and stress without failure. Titanium alloys have been used in weight-saving designs. Experience reports confirm that defense uses of titanium have fewer maintenance issues over time.

Stainless steels are one of the DFARS-compliant materials. The two most commonly used grades are 304 and 316L. The two are used where corrosion as well as wear resistance is required. They are used in military marine equipment and durable fasteners. Defense laboratory tests show that stainless steels maintain strength in varying conditions.

Composite materials also deserve special mention. Carbon-fiber reinforced polymers have also become a choice one. They offer extremely good strength-to-weight ratios. Composites are used in bodies of vehicles and armor by military manufacturers. In various tests, composites have been found to be resistant to high impacts and hence are ideal for safety devices. Their weather resistance also is a reflection of their suitability.

Specialty plastics such as polyether ether ketone are another product which is on this list. This is a thermoplastic that has aerospace and defense applications. It is heat and chemical-resistant. It has been used by numerous defense projects whenever regular metals would be too heavy or too reactive. It is a dependable product for long-term use.

Coated metals and proprietary alloys also feature on this list. These are other materials that also meet other standards such as wear resistance, anti-corrosion, and surface hardness. Some aluminum alloys, for example, are anodized to be made more durable. Field life has testified to the fact that coatings extend the life of a material. Proprietary alloys were designed specifically to fill the special demands of military equipment. Their composition is closely regulated by quality control teams.

Advanced ceramics are also on the list. Ceramics have uses in armor and electronics. They provide resistance to high temperatures as well as insulating properties that metals do not possess. Ceramics in defense technology bring a secondary protection against electrical currents and mechanical forces. Their use in critical defense elements has been reported in various technical journals.

|

Material Type |

Examples/Grades |

Common Uses in Defense |

Key Properties |

|

Aircraft structures, vehicle parts |

Lightweight, strong, corrosion-resistant |

||

|

Jet engines, missile components |

High strength-to-weight ratio, heat resistant |

||

|

Marine equipment, fasteners |

Corrosion and wear resistant |

||

|

Composite Materials |

Carbon-fiber reinforced polymers (CFRP) |

Vehicle bodies, protective gear |

High strength-to-weight ratio, impact resistant |

|

Specialty Plastics |

Polyether ether ketone (PEEK) |

Aerospace components, lightweight parts |

Heat and chemical resistant |

|

Coated Metals & Proprietary Alloys |

Anodized aluminum, military-grade alloys |

Corrosion-resistant and wear-resistant parts |

Surface-hardened, extended durability |

|

Advanced Ceramics |

Alumina, Silicon Carbide |

Armor, electronics, insulators |

High temperature resistance, electrical insulation |

For more advanced materials, please check Stanford Advanced Materials (SAM).

In summary, the roster of DFARS compliant materials is a convenient reference for defense contractors and engineers. The accepted materials include aluminum alloys, titanium alloys, stainless steels, composite materials, specialty plastics, coated alloys, and advanced ceramics. They are a blend of past and present testing. They all carry along a performance and reliability history in the military context.

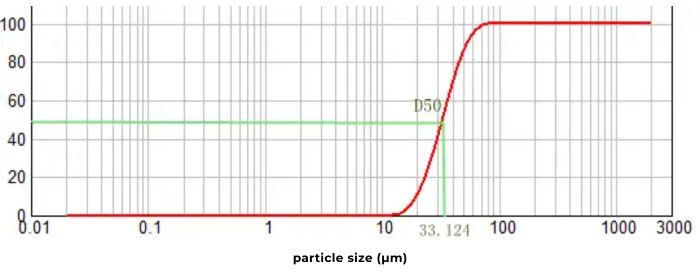

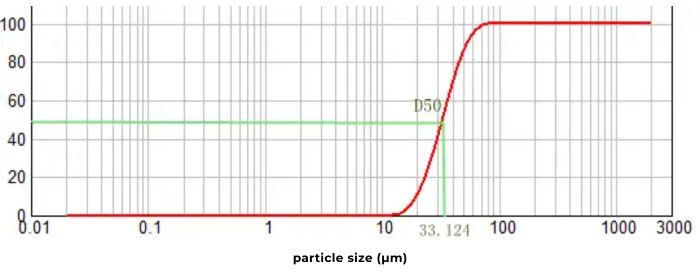

Stanford Advanced Materials (SAM) specializes in supplying DFARS-compliant alloy powders, including aluminum, titanium, stainless steel, nickel alloys, and cobalt alloys. In full compliance with DFARS 252.225-7009 regulations, all materials are sourced exclusively from the United States or approved allied nations. We provide complete traceability and certification services to ensure the safety, reliability, and regulatory compliance of your defense and aerospace projects.

Q: What are DFARS compliant materials used for?

A: They are used in defense and military projects to enable excellence in performance, safety, and durability.

Q: How is material compliance warranted by DFARS?

A: They are warranted through thorough testing, documentation, and quality checkup audits by independent manufacturers and testing labs.

Q: Are new materials allowed for the DFARS compliant list?

A: Yes, materials are regularly tested and updated depending on field tests and evolving defense requirements.