Magnesium oxide powder (MgO) is an inorganic compound composed of magnesium and oxygen elements, presenting as a white or grayish-white powder.

Magnesium oxide powder is an alkaline oxide, possessing the general characteristics of alkaline oxides and classified as a pozzolanic material. It is white or grayish-white, odorless, tasteless, non-toxic, with the chemical formula MgO. It has an extremely high boiling point of 3,600 °C and a melting point of 2,852 °C, with a density of 3.58 g/cm³ (25 °C). MgO is soluble in acids and ammonium salt solutions but insoluble in alcohol. MgO is biocompatible and friendly to human tissues.

In most chemical environments, MgO powder is highly stable and does not easily react with other chemicals. However, magnesium oxide powder has a certain moisture-absorbing capacity. When exposed to air, it easily absorbs moisture and carbon dioxide, gradually converting to magnesium carbonate. Therefore, it can be used for humidity control and moisture prevention.

Fig 1. Nano MgO Powder

With the upgrade of industrialization and the demand and development of high-tech functional materials markets, a series of magnesium oxide products have been developed and produced.

|

Type |

Characteristics |

|

High reactivity |

|

|

Low impurity content, excellent high-temperature resistance and electrical insulation properties |

|

|

40 nm, enhanced reactivity and catalytic performance |

|

How do the different types of Magnesium Oxide differ?

The light-burnt variant has a larger surface area for low-temperature applications, the fused type ensures high purity for industrial high-temperature needs, and the nano form offers small particles for high-tech and medical uses.

Stanford Advanced Materials (SAM) offers a variety of competitively priced magnesium oxide powder products. Please Get A Quote for more information.

Thanks to its outstanding physical and chemical properties, magnesium oxide powder demonstrates broad application prospects in multiple fields.

In the industrial sector, magnesium oxide powder is primarily used to manufacture refractory materials such as furnace linings, refractory bricks, and ceramic products. Its high melting point and excellent thermal stability make it a key raw material in steel smelting, glass manufacturing, and high-temperature processes. Additionally, magnesium oxide powder is used in the production of fireproof coatings, insulating materials, and paper fillers. Using magnesium oxide as a filler and additive can significantly enhance the physical properties and heat resistance of products.、

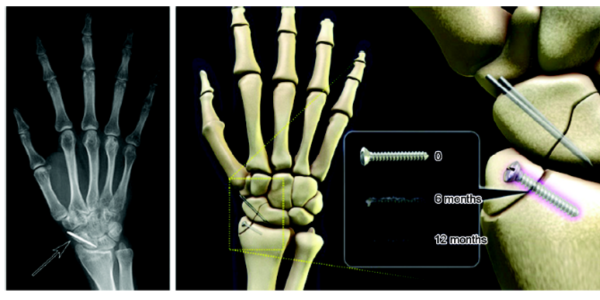

Magnesium oxide powder has various applications in the medical field, including as an antacid, laxative, and a component in supplements for magnesium. Additionally, as a bioceramic material, magnesium oxide is researched for bone repair and bone substitute materials due to its good biocompatibility and biodegradability. This helps promote the growth of bone cells and aids in new bone formation.

Moreover, studies have shown that MgO powder possesses anti-inflammatory and antibacterial properties, which help promote wound healing and prevent infections. Therefore, some artificial joints are coated with MgO to inhibit bacterial growth and reduce postoperative infections.

Fig 2. Magnesium alloy screws for hand fracture surgery

In the food industry, magnesium oxide powder is widely utilized not only as an anti-caking agent and nutritional supplement but also for its numerous health benefits, especially for older adults. It effectively prevents clumping in foods, thereby extending the product's shelf life and ensuring consistent quality.

As a rich source of magnesium, MgO serves as an essential magnesium supplement, supporting overall human health by enhancing bone density, muscle function, and cardiovascular health. Magnesium oxide is commonly added to vitamin supplements and mineral-fortified foods targeted towards older populations to address their specific nutritional needs. Additionally, it is used as an additive in food processing to adjust pH levels and maintain color stability, further enhancing the nutritional value and visual appeal of food products.

The application of magnesium oxide powder in the environmental sector is increasingly widespread. MgO can be used in wastewater treatment to remove heavy metal ions and acidic pollutants, thereby improving water quality. Data show that nano MgO powder can remove over 98% of heavy metal pollutants when treating chemical wastewater.[1] Additionally, magnesium oxide powder is used in gas purification to reduce harmful gases in industrial emissions, such as sulfur dioxide and nitrogen oxides. Besides gas treatment, it can also be used to amend waste soil. As a soil conditioner, magnesium oxide can adjust soil pH levels and promote plant growth.

Magnesium oxide plays multiple roles in cosmetics, such as a thickener, pH balancer, physical sunscreen, oil control agent, antibacterial agent, and concealer. The roles of magnesium oxide in skincare products include:

Magnesium oxide powder shows tremendous application potential in the new energy sector. Particularly in electrode materials for lithium-ion batteries and fuel cells, MgO acts as a stabilizer and conductive enhancer, improving battery performance and longevity. Additionally, magnesium oxide powder is used in the thermal management systems of electric vehicles to optimize the heat dissipation of battery packs, thereby increasing the overall energy efficiency of the vehicle.

With its exceptional physical and chemical properties, magnesium oxide powder plays a significant role in industries such as manufacturing, medicine, food, environmental protection, skincare, and new energy. As technology advances and application demands continue to grow, the application prospects of magnesium oxide powder will become even broader.

1. What types of products does SAM offer?

We provide various MgO options, including light-burned powder for refractory and electrical insulation uses, a fused variety with high purity suitable for steelmaking and ceramics, and nano-sized powder ideal for pharmaceuticals and advanced composites.

2. What are the main applications of MgO?

Our products are utilized in refractory linings, steel refining processes, dietary supplements, electrical insulation, environmental cleanup, and the production of high-performance building materials.

3. What is the best way to store the MgO powder?

Store in a dry, sealed container away from light and heat to prevent moisture absorption and maintain quality.

4. How is purity maintained?

Each type is processed to achieve high purity levels: light burned exceeds 99%, fused is above 99.5%, and the nano form is over 99.9%, meeting stringent industrial and medical standards.

5. How can I purchase these products?

Orders can be placed through our website, by contacting customer service for quotes, or by reaching out directly for any custom specifications.

[1] Perera, Chamanei & Gurunanthanan, Vijayakumar & Chib, Anoop & Mantilaka, Prasanga & Das, G. & Arya, Sandeep. (2024). MgO nanoadsorbents in wastewater treatment: A comprehensive review. Journal of Magnesium and Alloys. 12. 10.1016/j.jma.2024.05.003.

United States

.png)