With the continuous advancement of industrial technology, the demand for titanium powder has been steadily rising. Titanium and its alloys are renowned for their excellent properties, including low density, high specific strength, good heat resistance, and corrosion resistance. These materials are widely used in industries such as aerospace, shipbuilding, chemical engineering, machinery manufacturing, and hard alloys.

However, traditional titanium metallurgy processes have drawbacks such as long processing cycles, high energy consumption, and low material utilization rates. These issues result in higher production costs for titanium alloys, limiting their broader application. The elevated costs not only increase the burden on manufacturing enterprises but also hinder the promotion of titanium materials in small and medium-sized enterprises and emerging industries. Therefore, reducing the production costs of titanium and titanium alloys has become a crucial pathway to expanding their applications.

Against this backdrop, powder metallurgy technology has gradually become an important development direction in the titanium metallurgy industry. Powder metallurgy achieves near-net shape formation by shaping and sintering metal powders, significantly reducing material waste and improving resource utilization. Additionally, powder metallurgy processes use less energy and are more energy-efficient. They are also environmentally friendly. These processes allow for high-precision manufacturing of complex shapes. This shortens production cycles and increases production efficiency. As a result, powder metallurgy effectively reduces the costs of titanium alloys. It also promotes the use of titanium powder in more fields.

The quality and cost of titanium powder are extremely important for the quality of its powder metallurgy products. The preparation method directly affects the quality of the powder. Currently, the main methods for preparing spherical titanium powder include atomization, radio frequency plasma spheroidization, and plasma rotating electrode process. While, the main methods for preparing non-spherical titanium powder include hydrogenation-dehydrogenation and reduction methods.

1. Atomization Method

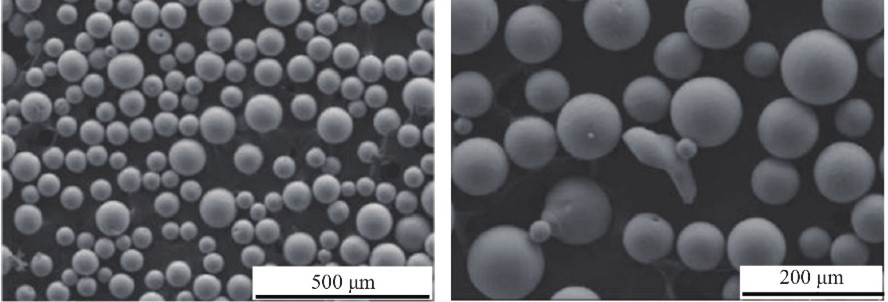

The atomization method is the most widely used method for preparing spherical titanium powder both domestically and internationally, mainly including gas atomization and plasma atomization.

Gas atomization involves the use of high-speed airflow to impact and break up molten metal, which is then rapidly cooled to obtain metal powder. This is currently the most common method for producing spherical titanium powder. The titanium powder produced by gas atomization technology has low impurity content and low oxygen content, making it suitable for additive manufacturing.

Plasma atomization involves placing wire-shaped titanium or titanium alloy under a plasma atomization fluid, where the material is melted and atomized simultaneously. The metal droplets form spherical particles under the action of surface tension.

Fig 1. Microstructure of the spherical titanium powders prepared by atomization method

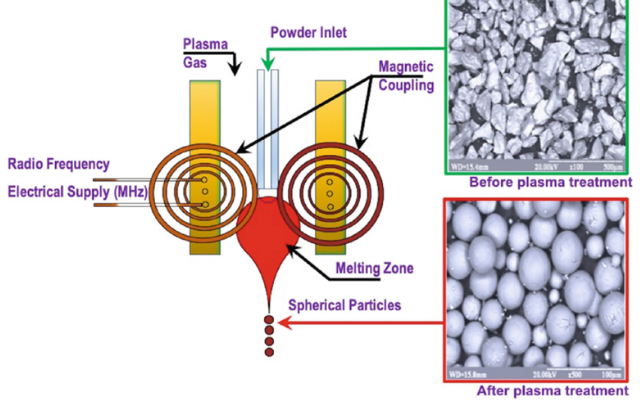

2. Radio Frequency Plasma Spheroidization Method

Radio frequency plasma spheroidization technology uses plasma to modify the shape of irregularly shaped powder to prepare spherical powder. Using irregularly shaped TiH2 as raw material, radio frequency plasma spheroidization treatment is applied to produce fine spherical titanium powder. Coarse TiH2 particles undergo hydrogen explosion, dehydrogenation, and spheroidization in the plasma region. By adjusting the feeding rate and carrier gas flow, the spheroidization rate can reach 100%, the yield of fine powder can exceed 80%, and there are no hollow powders or satellite balls, which significantly reduces the price of spherical titanium powder.

Fig 2. Diagram illustrating the Radio Frequency Plasma Spheroidization process used to produce ultra-pure powder from irregularly shaped material chunks.[1]

3. Plasma Rotating Electrode Process

The titanium powder produced by the plasma rotating electrode process has a smooth surface, is relatively dense, has good fluidity, and a narrow particle size distribution. The particle size of the powder can be adjusted by the rotation speed of the electrode.

Compared with the powder produced by gas atomization, the powder produced by the rotating electrode process does not have the common associated phases found in atomized spherical titanium powder, and the particle size is more uniform. However, the cost of titanium powder produced by this method is high, and it is currently generally used in the aerospace field.

1. Hydrogenation-Dehydrogenation Method (HDH)

The HDH method involves first producing hydride powders through hydrogenation and then obtaining metal alloy powders through dehydrogenation treatment. This method is simple, with easily accessible raw materials. The resulting titanium powder has a wide particle size distribution and low cost, making it the main method for producing non-spherical titanium powder.

2. Thermal Reduction Method

The thermal reduction method utilizes active metals such as sodium, magnesium, or calcium to reduce titanium salts or titanium oxides to produce titanium powder. The magnesium reduction method primarily produces titanium powder generated during the sponge titanium production process. However, due to the high content of impurity elements, it is rarely used specifically for titanium powder production. In contrast, sodium reduction produces titanium powder with high purity, especially low levels of oxygen, nitrogen, iron, and carbon impurities, and good flowability. It is considered one of the promising methods for producing titanium powder.

Summary: Preparation Technology of Titanium Powders

|

Method |

Raw Material |

Powder Morphology |

Powder Characteristics |

|

Hydrogenation-Dehydrogenation |

Electrolytic titanium or sponge titanium |

Irregular |

Low cost, simple process, wide particle size range, high O and N content |

|

Reduction Method |

Titanium tetrachloride or titanium dioxide |

Sponge-like |

Low O and N impurities, high purity, good flowability, requires subsequent separation process |

|

Atomization Method |

Titanium wire |

Spherical |

Low impurity content, good sphericity, uniform particle size, relatively coarse particles |

|

RF Plasma Spheroidizing Method |

Hydrogenated titanium particles |

Spherical |

High purity, good surface morphology, few internal voids, good flowability, more complex production technology |

|

Plasma Rotating Electrode Method |

Titanium rod material |

Spherical |

Smooth surface, high density, good flowability, narrow particle size distribution |

The primary methods for preparing spherical titanium powder include the atomization method, plasma rotating electrode method, and RF plasma spheroidizing method. The resulting powders feature uniform particle sizes and low specific surface areas but have poorer sintering performance. Their forming technologies include additive manufacturing and injection molding. Titanium powders produced by the hydrogenation-dehydrogenation method and reduction method are non-spherical, with higher impurity element contents. The forming technology is generally cold isostatic pressing, using simple equipment and low production costs.

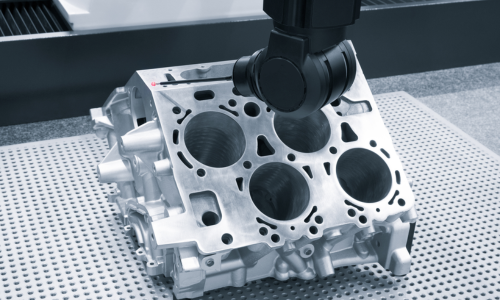

The rapid development of 3D printing technology has opened new avenues for the application of titanium and titanium alloy powders. In fields such as aerospace, medical devices, and automotive, titanium metal powder is widely used to manufacture complex, high-strength, and lightweight components.

Titanium metal, with its lightweight and high-strength characteristics, has become an ideal material for the aerospace industry. As the global demand for commercial aircraft, aerospace manufacturers' reliance on high-performance materials continues to grow. Titanium metal powder, as a raw material for manufacturing critical components such as aircraft structural parts, engine parts, and turbine blades, naturally sees a significant rise in demand.

The biocompatibility of titanium metal gives it a unique advantage in the field of medical implants. With the global aging population and increasing medical needs, the application of titanium metal powder in medical products such as orthopedic implants, dental implants, and cardiovascular stents is continuously expanding.

To improve fuel efficiency and reduce emissions, the automotive industry is actively seeking lightweight solutions. Titanium metal powder, as a raw material for manufacturing high-performance automotive components, is witnessing increasing demand. Its application is particularly widespread in racing and high-end automotive sectors.

Titanium alloy powder, through additive manufacturing technology, can produce complex micro-structured components that meet the precision and high-performance material requirements of modern electronic devices. For example, Apple plans to use titanium alloy bodies and titanium alloy hinges in its foldable iPhones to ensure durability and lightweight design. Using 3D printing for phone production allows for hollow designs, further reducing the weight of the chassis without compromising structural strength while also enhancing heat dissipation performance.

[1] Krishna, Ram & Mohan, Sreenivasan & Lyutyk, Mykola & Barosh, Mykola. (2021). Characterization of Spheroidized Alumina Powders for Ceramic 3D Printing Application. 10.1007/978-3-030-71956-2_20.

United States

.png)