At the forefront of this revolution is the fascinating realm of 3D printing powder – a medium that unlocks a new dimension of creativity and innovation. Let's delve into the enchanting process and possibilities behind the magic of 3D printing powder.

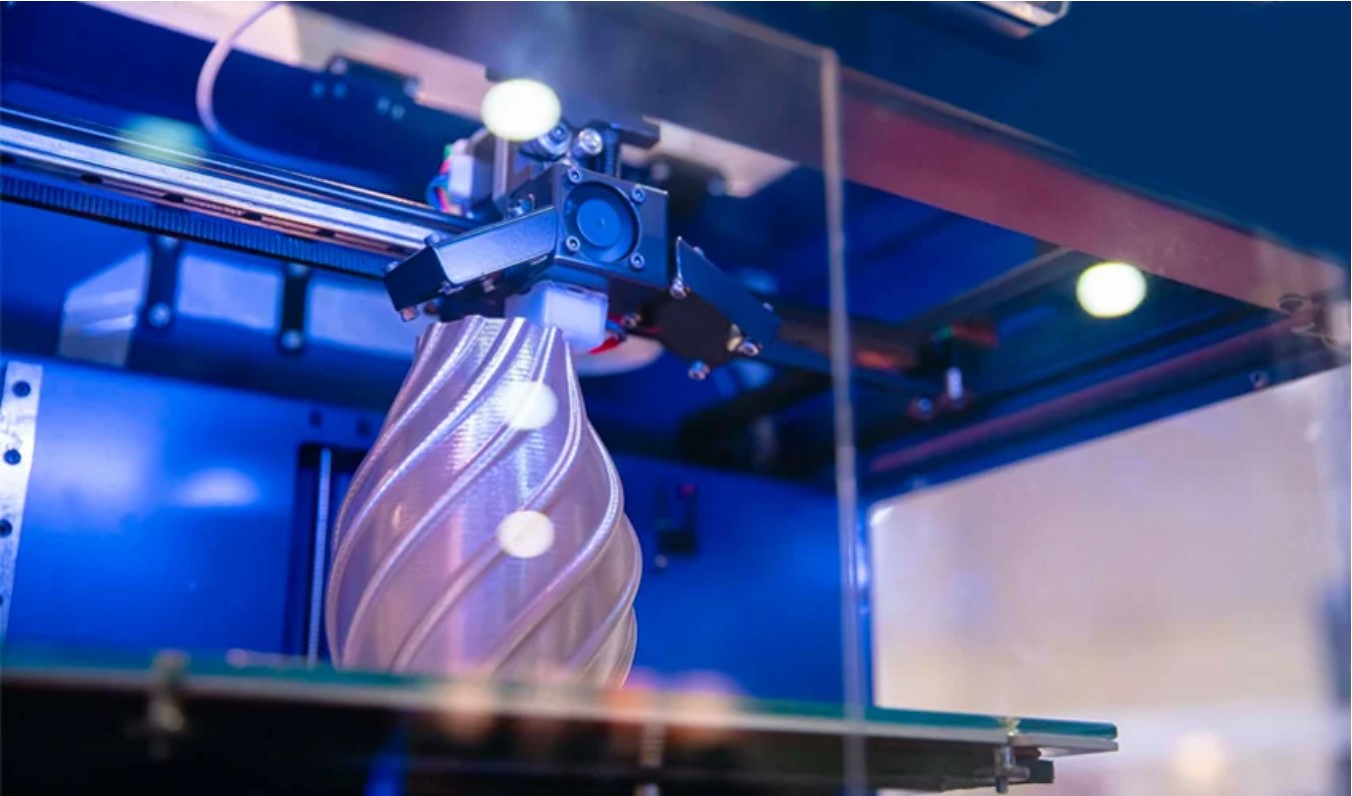

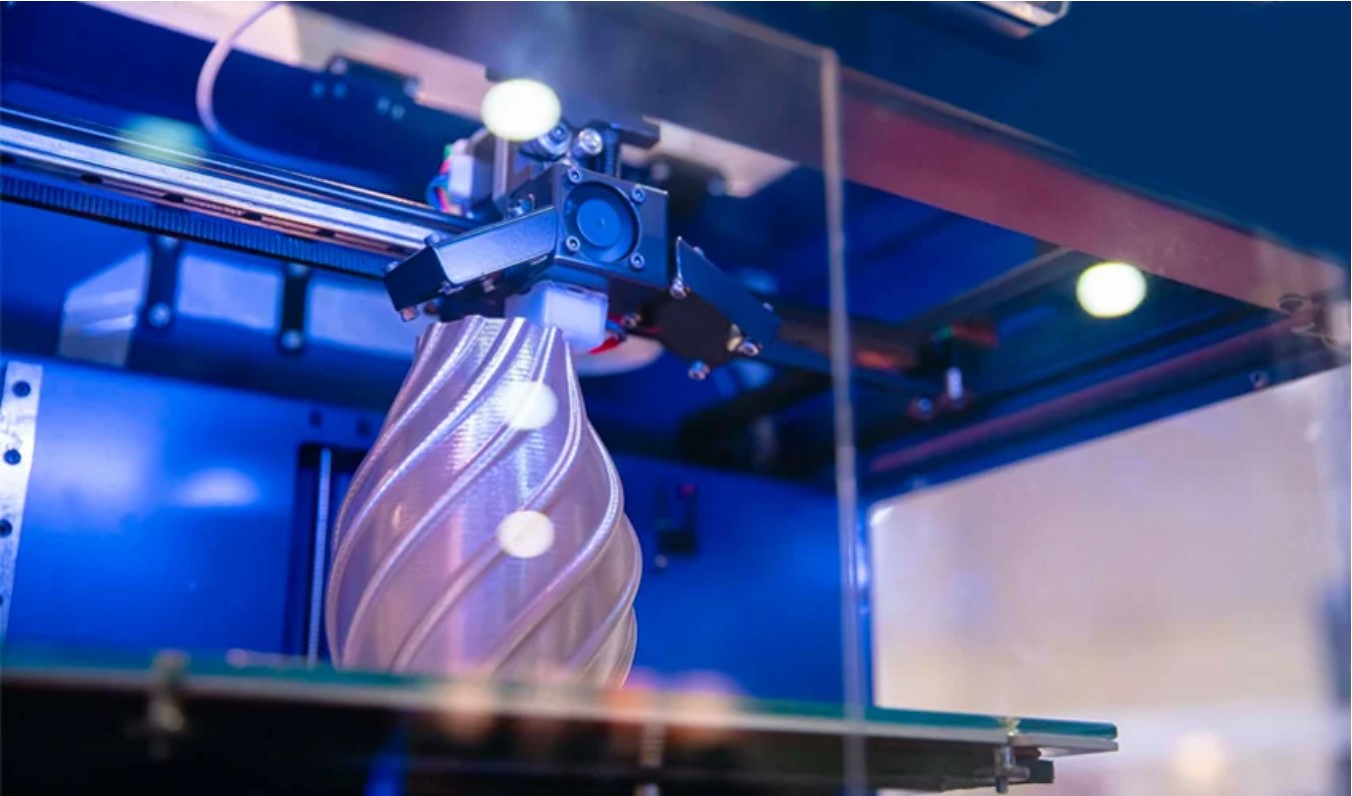

Unlike traditional subtractive manufacturing methods, 3D printing is an additive process that builds objects layer by layer. The use of powder as a printing medium introduces a whole new level of complexity and versatility. The process begins with a digital model, often created through computer-aided design (CAD) software. This model is then sliced into thin horizontal layers, serving as a blueprint for the 3D printer.

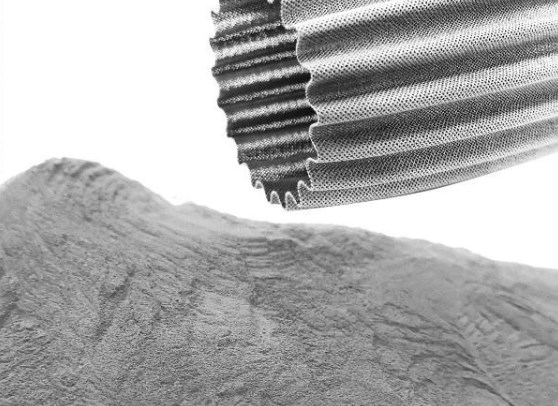

3D printing powder is not limited to a single material; it spans a diverse range of materials suited for various applications. Metals, plastics, ceramics, and even food ingredients can be used as printing powders. Each material offers unique properties, such as strength, flexibility, heat resistance, and electrical conductivity. This versatility makes 3D printing powder suitable for industries ranging from aerospace and healthcare to art and fashion.

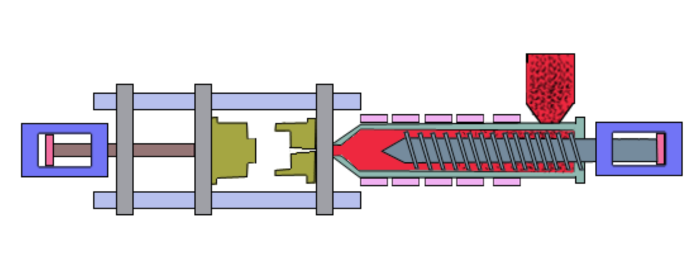

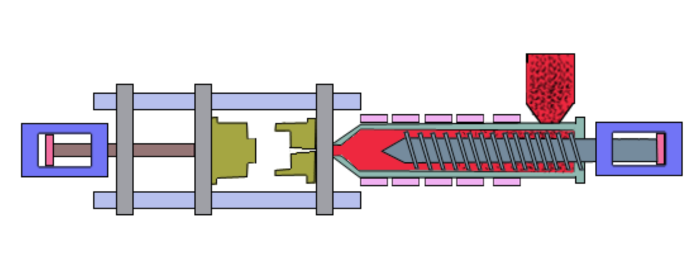

The magic begins as the 3D printer deposits a thin layer of powder material onto the printing platform. A precise laser or electron beam then selectively fuses the powder particles, solidifying them according to the design's specifications. Once a layer is complete, the platform drops slightly, and the process is repeated for the next layer. This layer-by-layer approach allows for intricate and complex designs that were previously unattainable.

3D printing powder unleashes design freedom that transcends traditional manufacturing constraints. Intricate geometries, hollow structures, and interlocking components can all be created without assembly. This opens up possibilities for highly customized, one-of-a-kind products, as well as streamlined production of complex prototypes and end-use parts.

The impact of 3D printing powder extends far beyond design studios. In healthcare, patient-specific implants and prosthetics are crafted with precision, improving both functionality and comfort. Aerospace engineers utilize lightweight metal components that were once unfeasible to manufacture. The art world embraces this technology to create sculptures that defy the boundaries of traditional materials.

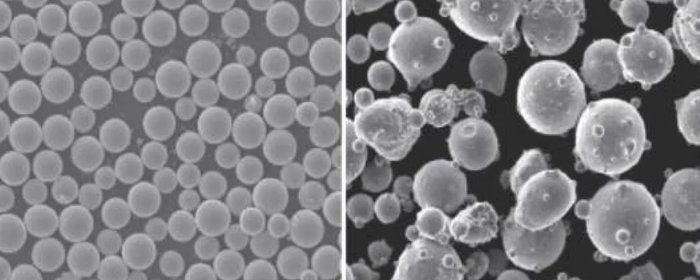

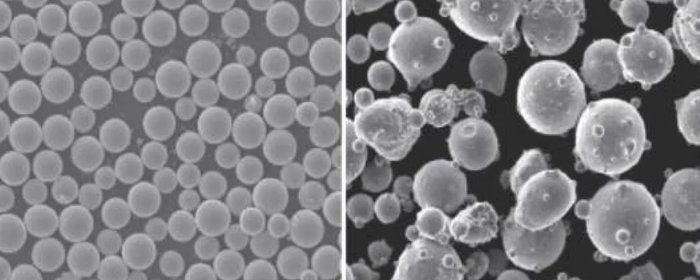

While 3D printing powder presents a multitude of advantages, challenges remain. Ensuring consistent powder flow, preventing contamination, and optimizing printing parameters are ongoing areas of research and development. However, the progress made is remarkable, and as technology advances, these challenges are gradually being overcome.

The magic of 3D printing powder transforms digital designs into tangible objects, unlocking boundless creativity and innovation. This revolutionary process redefines manufacturing, offering customized, intricate, and efficient solutions across industries. As materials evolve, techniques improve, and boundaries are pushed, the world can expect to witness even more breathtaking creations emerge from the enchanted realm of 3D printing powder.