Welcome to the world of stainless steel, where strength meets corrosion resistance, and versatility is the name of the game! In industries ranging from skyscraper construction to the fine details of watchmaking, stainless steel is the unsung hero.

Today, we're zooming in on a special form of this material—stainless steel powder. Used in everything from 3D printing to high-tech metallurgy, this powder is a game-changer. Join us as we dive into the nuances of 301, 304, and 316 stainless steel powders, guiding you through the labyrinth to make the most informed choice for your project.

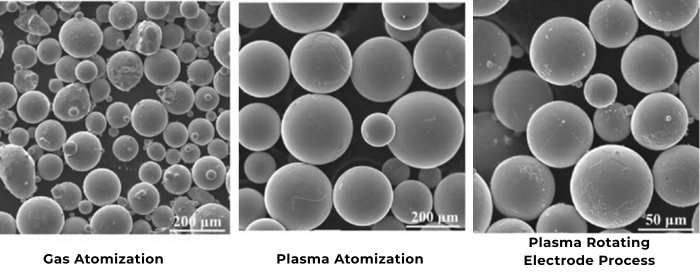

Stainless steel powder is essentially stainless steel that's been finessed into a fine powder. This transformation is usually achieved through atomization, a process that involves melting the steel and then blasting it with a jet of air or water to create tiny particles.

This powder plays a pivotal role in industries, finding its place in additive manufacturing for creating complex, durable components, and even in the cosmetics industry for its reflective properties. The trick lies in choosing the right type for your specific application—a decision that can make or break your project.

Before we dive deeper, let's get acquainted with our contenders:

301 Stainless Steel Powder: Known for its high strength and commendable corrosion resistance. It's like the Hercules of stainless steel powders.

304 Stainless Steel Powder: The Jack-of-all-trades with excellent corrosion resistance and formability. Think of it as the friendly neighbor who's good at everything.

316 Stainless Steel Powder: With superior corrosion resistance, especially against chlorides, it's the superhero of stainless steels, saving the day in the harshest environments.

301 stainless steel powder is the go-to for projects requiring strength and durability. It shines in applications like spring manufacturing and structural components, where resilience is key. The pros? It has high strength and good corrosion resistance. The cons? It's not the best swimmer in saltwater or chlorinated environments.

304 stainless steel powder is your versatile friend, perfect for a wide range of applications—from automotive parts to kitchen appliances. It boasts excellent corrosion resistance and formability. However, it does have its Achilles' heel: it's not as resistant to chlorides as its cousin, 316.

316 stainless steel powder is the cream of the crop when it comes to fighting off corrosion, especially from chlorides and acidic substances. It's ideal for medical implants, marine hardware, and chemical processing equipment. The downside? This level of resistance comes with a higher price tag.

When we look at 301, 304, and 316 stainless steel powders side by side, we need to think about their strength, how well they resist rust, and how much they cost.

Breaking it down, 301 is strong and pretty good at resisting rust, all without breaking the bank.

304 is the all-rounder, offering a nice mix of being easy to shape and fighting off rust well.

On the other hand, 316 is the superhero when it comes to beating rust, especially from salt and acids. So, if you've got a tough job, 316 is your go-to choice.

|

Property |

|||

|

Strength |

High |

Moderate |

Moderate |

|

Corrosion Resistance |

Good |

Excellent |

Superior |

|

Formability |

Good |

Excellent |

Good |

|

Best Used For |

Structural components, springs |

Wide range of applications, from automotive to kitchenware |

Harsh environments, marine applications, medical devices |

Selecting the right stainless steel powder requires a careful analysis of your project's environment, mechanical demands, and budget. Consider the exposure to corrosive substances, the need for strength versus formability, and how much you're willing to invest. Sometimes, consulting with a material scientist or engineer can illuminate the path to the best choice. Of course, we have also listed some frequently asked questions for you.

Q1: What’s stainless steel powder used for?

A1: Stainless steel powder is super versatile! It's used in 3D printing for making intricate parts, in metallurgy for making strong metal components, and even in cosmetics for that shiny effect. It's all about creating things with precision and durability.

Q2: How do I decide between 301, 304, and 316 stainless steel powders?

A2: It all boils down to your project's needs. If you're looking for strength and a friendly price, go for 301. For a great mix of easy shaping and rust resistance, 304's your guy. And if you’re facing tough environments, especially with salt and acids, 316 won’t let you down.

Q3: Is 316 stainless steel powder much more expensive than 301 or 304?

A3: Yep, 316 usually costs more because it's like the superhero of rust resistance. But remember, you get what you pay for, especially if you need that extra protection.

Q4: Can stainless steel powder be used for outdoor projects?

A4: Absolutely! Especially 316 powder, thanks to its awesome resistance to corrosion. Perfect for anything that’s going to brave the great outdoors.

Q5: How important is corrosion resistance for choosing stainless steel powder?

A5: Super important! If your project might get wet or be exposed to chemicals, picking a powder with good corrosion resistance, like 304 or 316, can save you a lot of headaches later.

Q6: Can I use 304 stainless steel powder for 3D printing?

A6: For sure! 304 is a popular choice for 3D printing because it's pretty easy to work with and has good corrosion resistance, making your printed parts look good and last long.

Q7: What should I consider if my project involves contact with food?

A7: Hygiene is key here, so 304 and 316 are great choices because they're food-safe nd resist corrosion well, which means they're easy to clean and keep germ-free.

Q8: Is there a difference in the way 301, 304, and 316 stainless steel powders are processed?

A8: The basics are similar, but the specifics can vary a bit to enhance their unique properties. For example, the process might be tweaked to improve 316’s corrosion resistance or 301’s strength.

Q9: How does mechanical strength play into my choice of stainless steel powder?

A9: If your project needs to withstand a lot of pressure or weight, you’ll want a powder with high mechanical strength. 301 is known for its strength, making it a solid choice for heavy-duty applications.

Q10: What if my project is on a tight budget?

A10: Budget is always a key factor. If cost is a big concern, 301 is generally less expensive and still offers good strength and corrosion resistance. It's a great way to get the benefits of stainless steel without the higher price tag of 316.

Navigating the world of 301, 304, and 316 stainless steel powders can be complex, but understanding the unique properties and applications of each can lead to successful project outcomes. Whether you're building the next architectural marvel or designing a medical implant, the right choice of stainless steel powder can make all the difference.

Eager to explore the possibilities of stainless steel powder for your next project? Dive into our resources for more information at https://powder.samaterials.com/. Let's create something remarkable together with the right stainless steel powder at your side!