Micro Tungsten Carbide Powder (Micro WC Powder) is a fine, high-purity refractory alloy powder composed of tungsten and carbon atoms in the form of microparticles. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Micro Tungsten Carbide Powder (Micro WC Powder).

Related products: WC-Co6 Powder, WC-Co12 Powder, WC-Co17 Powder, WC88-Co12

Micro Tungsten Carbide Powder (Micro WC Powder) is a fine, high-purity refractory alloy powder composed of tungsten and carbon atoms in the form of microparticles. Stanford Advanced Materials (SAM) has rich experience in manufacturing and supplying high-quality Micro Tungsten Carbide Powder (Micro WC Powder).

Related products: WC-Co6 Powder, WC-Co12 Powder, WC-Co17 Powder, WC88-Co12

Tungsten carbide powder is produced through a refined manufacturing process that guarantees high purity and consistent quality. Known for its outstanding hardness, durability, and resistance to wear, this high-performance powder is ideal for creating cutting tools, dies, and various wear-resistant components. Its excellent thermal and electrical conductivity also broadens its applications, ensuring reliable performance across industries like automotive, aerospace, and mining.

|

Chemical Formula |

WC |

|

CAS No. |

12070-12-1 |

|

Particle Size (μm) |

0.5 to 60 |

|

Melting Point |

2870℃ |

|

Purity |

99.9% |

|

Morphology |

Hexagonal |

Chemical Composition

|

Particle Size (μm) |

Chemical Composition (%) |

|||||

|

Oxygen |

Total C |

Free C |

Combined C |

Fe |

Mo |

|

|

0.9-1.1 |

0.15 |

6.15±0.05 |

0.06 |

6.07 |

≦0.020 |

≦0.010 |

|

1.2-1.4 |

0.12 |

6.13±0.05 |

0.06 |

6.07 |

≦0.020 |

≦0.010 |

|

1.4-1.6 |

0.10 |

6.13±0.05 |

0.05 |

6.08 |

≦0.020 |

≦0.010 |

|

1.8-3.2 |

0.07 |

6.13±0.05 |

0.05 |

6.08 |

≦0.020 |

≦0.010 |

|

3.3-6.0 |

0.05 |

6.13±0.05 |

0.05 |

6.08 |

≦0.020 |

≦0.010 |

|

6.0-7.5 |

0.04 |

6.13±0.05 |

0.05 |

6.08 |

≦0.020 |

≦0.010 |

|

7.5-10 |

0.03 |

6.13±0.05 |

0.05 |

6.08 |

≦0.020 |

≦0.010 |

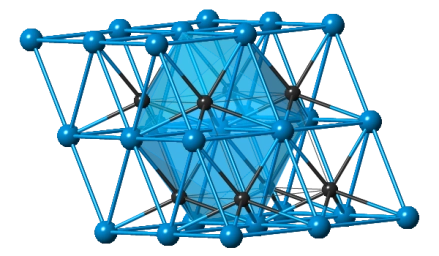

Tungsten carbide powder molecular structure

Cutting Tools: Micro tungsten carbide powder is commonly used in the manufacturing of cutting tools, including drills, saw blades, milling cutters, and turning tools. Its superior hardness, wear resistance, and stability at high temperatures make it ideal for cutting and machining.

Mining and Drilling: It is essential in producing drilling bits, inserts, and other wear-resistant parts for mining and drilling operations. Its hardness and abrasion resistance are well-suited for drilling through rock, concrete, and other hard materials.

Metalworking: Micro tungsten carbide powder is utilized in metalworking tools such as dies, punches, and forming tools, allowing for high-speed machining, enhanced precision, and extended tool life.

Wear Parts: Used in manufacturing nozzles, valves, bearings, and seals exposed to abrasive environments, it provides lasting durability and reduces maintenance costs in wear-intensive applications.

Aerospace and Defense: This powder finds extensive use in aerospace and defense, particularly for turbine components, armor-piercing ammunition, and missile parts, where strength, hardness, and heat resistance are critical.

Automotive Industry: It is applied to create wear-resistant components for engines, transmissions, brakes, and suspension systems in automotive manufacturing, improving performance, reducing friction, and extending part lifespan.

Medical and Dental Tools: Micro tungsten carbide powder is used in producing surgical instruments, orthodontic brackets, and dental drills, offering the precision and durability essential for medical and dental applications.

Electronics: In electronics, it is used for electrical contacts, heat sinks, and circuit-mounted components, providing excellent electrical conductivity, thermal stability, and mechanical strength.

Energy Industry: It has applications in the energy sector, particularly in oil and gas drilling tools, wear-resistant parts for power generation equipment, and components in renewable energy systems like wind turbines.

Our Micro Tungsten Carbide Powder (Micro WC Powder) is carefully handled during storage and transportation to preserve the quality of our product in its original condition.